On comparison to hydraulic powered garbage compactor and pneumatic powered garbage compactor, the efficient version of the garbage compactor is the hydraulic compactor. Its functioning differs from the pneumatic crusher. The functioning of the hydraulic compactor is on Pascal’s principle of pressure. These garbage compactors make use of the centrificial force, extra down pressure and the necessary vibration to crush the waste materials. These reduce the waste materials to finer components or sheets to generate the desired results. In comparison to the pneumatic garbage compactors, the hydraulic compactors offer greater efficiency as they reduce the waste products to much finer form or shapes. However, due to the complex machinery, they tend to be a little expensive than the pneumatic crushers.

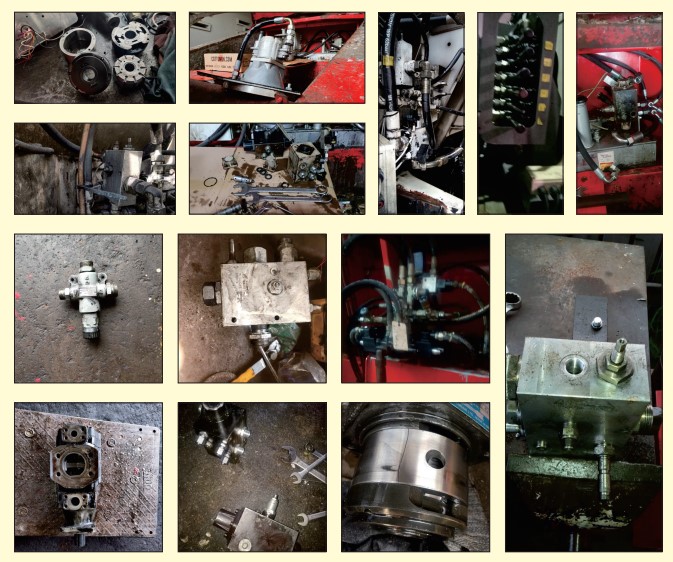

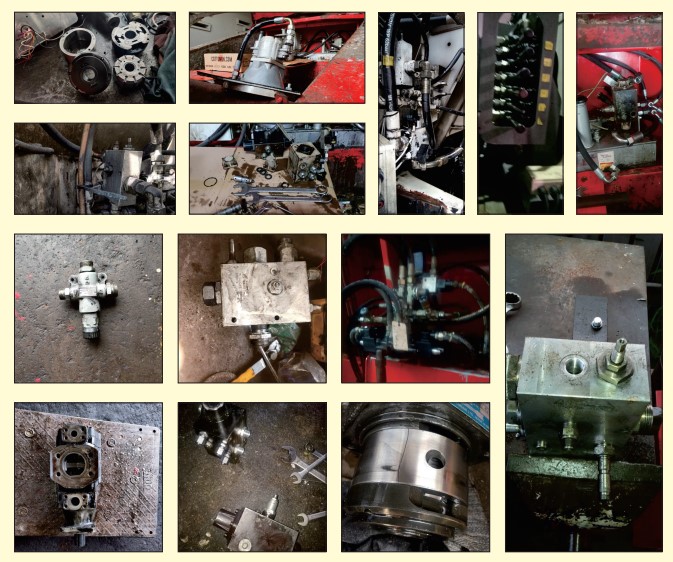

- Hydraulic refuse compactors with rear end loading perform the compression process with the successive movements of the slide-blade after the garbage in the garbage bin is emptied into the hopper.

- The garbage in the garbage bin is taken into the hopper and compacted with an automatic control mechanism. Mechanical control performed with the help of mechanical arms is offered as another option.

- The loading and unloading of garbage are performed automatically in the cabin, by means of the buttons on the side and the rear of the body. The unloading process is performed by a mechanism consisting of a bidirectional cylinder and ejection plate. During this process opening and closing movements of the tail gate take place automatically.

- The bin lifter is designed to be suitable for lifting bins specific to the country, as well as European type bins and offered to the use of the customer.

- The rear loader hydraulic compactor is a quick and economical solution for waste collection. It provides the user with a safe and satisfactory working opportunity. It adds a modern, clean, and developed appearance to the environment.